Turning Data into Performance: How Biogas Plants Unlock Hidden Value

What if the most valuable source of profitability in your biogas plant wasn’t a new piece of equipment, a cheaper feedstock, or a redesigned tank … but your data?

For years, the biogas industry has focused on optimizing the tangible: refining feedstock recipes, upgrading components, and improving system design. These improvements matter but they’ve brought us to the edge of what physical changes alone can deliver. The next leap in performance won’t come from what we can touch. It will come from what we can see and understand.

Understanding the Hidden Layer of Opportunity

Across digestion systems, volatile solids destruction ranges are well established. Wastewater digesters typically fall in the 50–60% range. Dairy manure digesters span roughly 45–65%, depending on design, co-digestion, and operational discipline. These ranges are well supported across operator training materials, EPA studies, and peer-reviewed research.

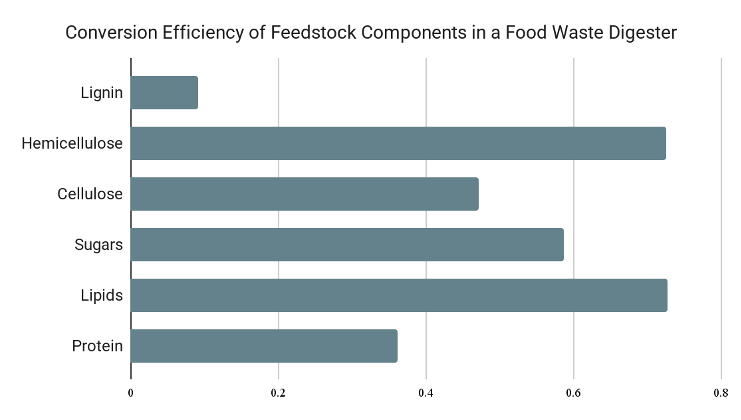

Yet even within these expected performance ranges, component-level insight reveals substantial untapped potential. As the chart illustrates, conversion efficiency varies sharply across substrates: lipids and sugars convert efficiently, cellulose and protein lag considerably, hemicellulose is variable, and lignin remains largely unconverted.

Every feedstock stream has its own metabolic fingerprint. Without real-time visibility, operators cannot see where they are capturing value and where they are quietly losing it.

Most plants still rely on retrospective, single-point data to manage biological systems that change by the hour. Spot samples cannot reveal microbial shifts, substrate breakdown dynamics, or early-stage process bottlenecks. This forces operators into reactive management, solving yesterday’s issues rather than optimizing for today.

From Observation to Anticipation

The next revolution in biogas optimization isn’t mechanical: it’s digital.

Alchemyca’s platform bridges the gap between what is happening biologically and what operators can see in real time. By integrating operational inputs across biology, process, and economics, the platform unlocks the decision layer: the point where data becomes understanding, and understanding becomes action.

With this visibility, operators can:

• target root causes rather than symptoms

• manage variability by tracking how feedstock characteristics shift load to load

• forecast performance using long-term data trends

• prevent upsets instead of responding to them

The result is a transition from reactive troubleshooting to predictive optimization.

The Business Case for Data Intelligence

The financial implications are meaningful. Substrates such as cellulose and protein represent valuable methane potential that is currently only partially realized. Increasing conversion efficiency even modestly across these lower-performing fractions can strengthen overall yield, operational consistency, and return on investment.

This isn’t about adding another dashboard. It’s about creating a unified intelligence layer that transforms how decisions are made, linking biological performance directly to operational and financial outcomes.

The Future of Biogas Profitability

For decades, the industry’s progress has been driven by mechanical innovation. The next frontier is digital: understanding, interpreting, and acting on the data that digestion systems generate every minute.

Alchemyca’s mission is to help operators turn complex biological signals into clear, actionable intelligence so plants can move from observation to anticipation, and from incremental improvements to meaningful, measurable gains.

The time for guesswork is over. The data has always been there. Now, Alchemyca makes it work.